|

BASIC INDIAN FACTS

World over, rebars are specified for use in RCC by the Yield Strength, India

being the exception. Till the start of this century nearly all structural designers in the country talked in terms of CTD

or Torsteel rebars only. The dominance of CTD bars in the civil industry was so profound since early 1970s that most civil

engineers had become guilty of assuming that these were of Grade Fe 415 of IS 1786-1985. Hardly anyone really bothered to

check the yield strength, ultimate tensile strength or the elongation when using CTD rebars in RCC. It was nearly always taken

for granted that these bars meet the IS code specified. Today, it has become fashionable to talk in terms of ‘TMT’

rebars. And probably out of habit acquired over the past few decades, the gullible civil engineer has again merely assumed

that these ‘TMT’ bars are of the specified Grade Fe 415 but in many ways superior to the old CTD bars. The many

civil engineers that the author has spoken to in the past few years were surprised to learn that the blind use of TMT bars

as available from stockists and traders is not a guarantee of a superior product.

|

|

|

|

|

|

|

|

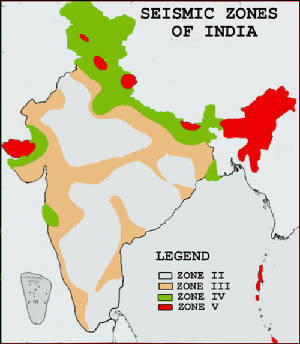

The Indian citizen has a right to know whether the house he stays in is a safe one that has been built with proper

materials. Indian life is as precious as that of those in other countries. The world recognises an Indian as a person of high

intellect who can contribute a lot to society. We must do what is necessary to protect his life as much as possible. Then

again, we must appreciate that about 50-60% of the Indian land mass falls under the seismic 3, 4 & 5 categories. (See

Seismic Zone Map). So, safety of construction is of prime importance in the country. There is no place for casualness or complacency

with regard to rebars.

|

| Seismic Zones of India |

A study

of world trends is useful in deciding on what needs to be done here.

|

|

|

|

|